How To Age A Nail

Nails as clues to age

Most anybody knows that handmade nails are older than machine made nails. But could you identify a handmade nail if y'all saw one? And could you separate an quondam nail from a reproduction blast? In addition to looking at how onetime nails were made, this article will besides discuss how to examine smash holes, rust left by nails plus where, how and why specific types and shapes of nails were used.

How nails work

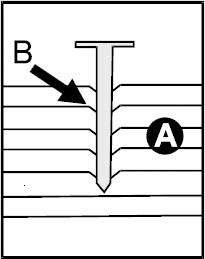

Nails, modern or antique, are able to be used as fasteners because of the cellular construction of forest on the microscopic level. As a boom is driven into wood, the tip of the boom pushes apart or crushes woods cells in its path (Fig. 3-A). When the tip of the nail passes, the cells leap dorsum and try to resume their old positions. This applies pressure to the nail shank (Fig. three-B) in the opposite management of the blast path and creates resistance which holds the nail in place. The principle is the same for all nails old or modern regardless of shape or how they were made. Mathematical formulas tin can accurately predict the belongings ability of nails based on size of smash, depth nail is driven, and the species and moisture content of the woods.

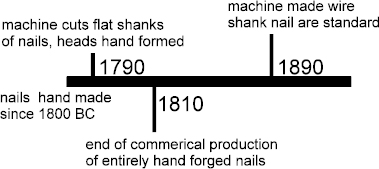

Nails accept been in apply since the offset of the Bronze Historic period, ca. 1800 B.C. From that time to the beginning of the 19th century, ca. 1790-1810, well-nigh nails were made entirely by mitt at the forge. A nail cut machine designed in the 1790s cut the blast's shank and reduced hand labor to only forming the caput of the nail. At the time of their introduction, these motorcar cut nails were sometimes referred to as "common cold nails" because they were not made at the forge. These machine/handmade nails were used up to the end of the 19th century. Past the 1890s, the entire smash was completely automobile formed producing the rounded shank or wire blast that continues in utilize today.

American hand wrought nails--those made entirely by hand or headed by hand--were washed by metal workers specializing in nail-making as well every bit blacksmiths who fabricated nails part time or to order. The work was hard and gave ascension to an early expression, "to work like a nailer" used to describer whatever intense activity. Nigh of these nails were formed from a nail rod, a bar of fe bachelor from iron mills shut to the gauge size of the blast. Nail rods were at showtime imported by American blast makers from mills in England but later used bars made in the colonies.

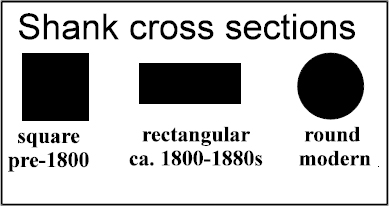

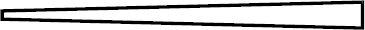

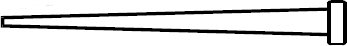

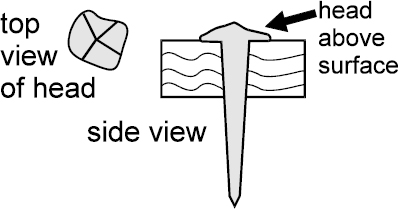

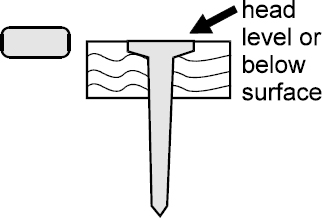

The first stride in making a hand forged smash was to form the shank. Next, the head was formed with a heading tool (Figs. 5-B & C). Early nails take two types of heads: a round head whose head is to a higher place the surface of the wood and used for full general purpose fastening and a T-head whose caput is driven below the surface and used for terminate work. The forged round head nail is also called a rose head considering the hammered head ofttimes resembles the petals on a rose. A variation of the T-head, the L-head, is the aforementioned as a T-head but with half the head cut off. Cross sections of pre-1800 nails are generally square; shanks from 1800-1890 are rectangular; modernistic shanks are round.

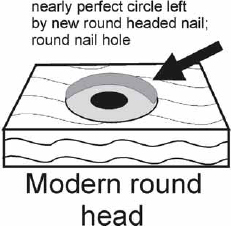

The earliest forged nails are identified by their irregular shanks and hammer marks on both shanks and heads. When viewed from above, early round heads accept a meandering outline that is anything but round. Later machine cut shanks will withal show hammering which was necessary to form the head. Fully machine-made nails used since the 1890s have circular shanks and round heads similar those in Fig. 6. Modernistic heads in item are virtually always a nearly perfect circle.

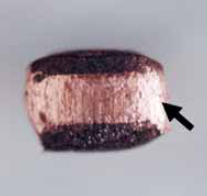

Reproductions of hand made blast shapes are currently being fabricated past casting in a mold. These new cast pieces typically show mold seams and/or grinding marks where the mold seams have been removed. Generally, this ways forth the shanks and across the heads. Rather than a broadly dimpled hammered surface, cast nails have a very gritty textured surface. Some belatedly 19th century nails were cast but had very limited use. In full general, whatsoever nail with molds seams or grinding marks should be considered of contempo industry. Some genuinely former cut nails with manus forged heads may accept burrs along the edges of their shanks. These burrs should not be confused with grinding marks that appear in the middle of the shanks and heads.

What you can larn from nail holes

Pieces that have been around for 150+ years frequently have at least a few original nails either missing or replaced. Looking at the holes left by the missing nails can provide valuable data.

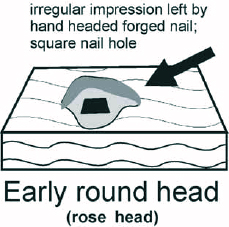

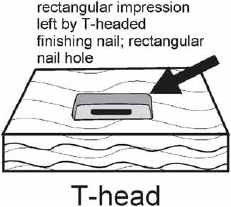

The irregular forged heads of early nails, for example, get out an irregular impression in the wood. Perfectly round heads on modernistic wire nails leave an most perfect circle impressed in the wood; early finishing T-heads leave a rectangular impression (Figs. 13-15). Irregular impressions from early round headed nails are correct in hidden or unseen places such equally backs and sides of drawers, backs of cases, etc., which is where they were originally used. Finding rectangular impressions from early finishing head nails in those same locations is wrong--the small T-headed finishing nails were used in exposed areas. The caption is oft that genuinely onetime forest that at one fourth dimension was visible has been used to repair, or entirely supervene upon, the original wood, or that the entire piece is a totally fabricated upwardly. It either example, the types of boom caput impressions tin exist a clue that the piece is, at the to the lowest degree, not original, and at the worst, a deliberate fake.

Pay particular attention to molding, trim and other outside details. In these positions y'all should expect to find small T-caput finishing nails driven flush with the surface on early on furniture. You should not observe tiny filled in nail holes which are generally a sign that modernistic round headless finishing nails have been used.

A few replaced nails are probably honest repairs and can actually raise a pieces' claim to legitimate and normal article of clothing and assist cosign historic period. Wholesale replacement or nails mismatched to their original function are a warning sign of potential problems.

Color of the boom hole

The condition of the wood surrounding nail heads and boom holes can provide additional clues about historic period. Early forged nails are a type of wrought iron with very low amounts of carbon typically about 3 to four per cent. This type of atomic number 26 has a very high resistance to corrosion. That's why wrought fe was used for early architectural features like balustrade railings, gates and other pieces meant to exist used outdoors. In improver to the low carbon, forged nails are also somewhat protected by the fire scale which forms on the surface every bit a result of being heated in the burn.

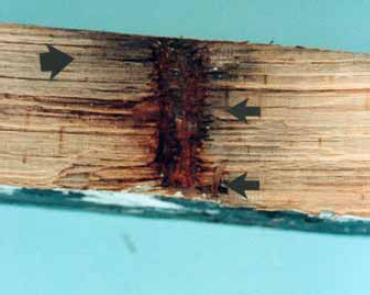

The loftier resistance to corrosion is due to how low carbon iron oxidizes, or rusts. When exposed, it develops a blackrust (Iron304) that does not fleck off. This stable motion picture of rust actually prevents further corrosion by keeping oxygen abroad from the underlying metallic. Blood-red/dark-brown rust, (Atomic number 26ii03) is the more common type of rust that causes serious flaking and damage to fe with college amounts of carbon. This rust is typical of nigh new cast iron reproductions.

Knowing how atomic number 26 corrodes and what colors of rust are formed, helps the states tell what types of nails were used even if the original nail is missing. When an early wrought iron nail corrodes, or rusts, it leaves a blackness stain in the forest effectually the blast hole. Newer nails fabricated of iron with higher carbon get out reddish/brown rust stains in the wood. The extent and penetration of discoloration caused by either blazon of rust depends on the type of wood and where a slice has been used or stored. Some wood, similar oak, take very strong natural acids and tend to produce deeply saturated stains.

Be sure that the condition of the nail matches the surrounding wood. It is a common exercise for forgers to combine old wood and old hardware--including nails--from several genuinely onetime derelict pieces to make one "expert" piece. If the wood effectually the smash head is blackened, then the nail should be blackened as well. Removing a rusty boom from rust-free woods is a danger signal that should cause immediate suspicion.

You should never base of operations your evaluation of a piece on one piece of evidence alone. The presence of manus forged nails is not a guarantee of historic period by itself. Analyzing nails, smash holes and the blazon of nails used in diverse locations is merely one step in gathering information upon which to base your conclusion of age and condition. Early forged nails salvaged from onetime pieces and modern reproductions shaped like early nails are easily obtained. A healthy skepticism is your best defense confronting a simulated. And Always enquire permission earlier y'all conduct your inspection.

Fig. ane (New) Reproductions which resemble old circular head nails. Sold as "collector's items".

Fig. ii (Old) Grouping of typical circular head hand forged nails. Look for hand hammered surfaces, irregular heads and shanks.

Fig. 3 Tips of nails crush or split the cells of forest (A) as they are driven in. Equally the tip of the blast passes, cells spring back putting pressure on the nail (B). This pressure holds the nail in place and makes information technology difficult to withdraw.

Fig. four Approximate time line of the evolution of nails

Fig. v-A

Fig. v-B

Fig. five-C

Fig. 5-D

Figs. 5 A-D. Forged or machine cut shanks (A) had heads shaped past heading tools (B & C). Heads were formed by hammering to complete the finished nail (D).

Fig. 6 New machine fabricated wire nails with round shanks similar these have been used from the 1890s. Flat head common nails top and bottom are for general utilise; modern finishing nail, center.

Fig. 7 Round head

Fig. 8 T-head

Figs. vii-eight There are 2 types of heads found on American hand forged nails. They are the circular head, a general purpose nail and the flat T-head used as a finishing nail in cabinetry and other detailed pieces.

Fig. 9 (New) View of mold seam in new cast nail. Such a seam would never announced in a hand forged nail or a machine cutting smash with forged head. Discover rough gritty surface texture instead of hammered surface on forged nails. Shown nigh 3X actual size.

Fig. 10 (New) Shut upwardly showing crude grinding marks forth mold seam on new cast nail. This example shown virtually 3X actual size.

Fig. 11 Head of new cast smash showing grinding marks along mold seam.

Fig. 12 Domed head of new cast smash reproduced today. In full general, nigh all cast nails are of contempo manufacture.

Nailhead impression & nail holes

Fig. 13

Fig. 14

Fig. 15

Fig. sixteen Elevation view of blast hole. Large arrow shows black stain where original nail was for many years. Minor arrows signal to more than contempo red/brown rust formed by modern smash placed in the same nail hole.

Fig. 17 Cross section of the nail pigsty from Fig. xvi. Big pointer points to blackened area left by early original nail. Small arrows point to recent cherry/brownish rust left by new nail in the same hole.

Fig. 18 (New) Reproductions of early finishing nails with flat heads and apartment tapering shanks. These new nails are cast in molds. Look for mold seams and grinding marks which never appear on accurate early on nails.

Fig. 19 (Old) Grouping of typical onetime nails with apartment T-heads and apartment shanks used in finish piece of work. These were at offset made entirely past hand. After, a motorcar cut the flat shanks and the heads were formed by hand.

Source: https://www.realorrepro.com/article/Nails-as-clues-to-age#:~:text=In%20general%2C%20any%20nail%20with,of%20the%20shanks%20and%20heads.

Posted by: whittenforris.blogspot.com

0 Response to "How To Age A Nail"

Post a Comment